From land to sky, Saudi Arabia’s construction and engineering feats have gone from highly industrial to innovatively accessible. Among the largest globally, Saudi Arabia’s construction pipeline exceeds $1.5 trillion in active developments; essentially building the equivalent of a new “Manhattan” in the Kingdom every year. These “giga-projects” are transforming the landscape and pushing engineers to deliver façade solutions at unprecedented speed and complexity.

With a perception based on geography rather than skill or innovation, Saudi Arabia was once seen as ill-equipped to showcase the latest technologies in construction and engineering, but today they are leading them.

The 205th edition of the international conference, ZAK the World of Facades, was held in Riyadh in December at the close of 2025. “ZAK” as it’s called by the faithful, brings top façade engineers and building envelope specialists from around the world to the Kingdom each year. The 2025 event showcased cutting-edge building envelope innovations tailored to extreme conditions. It also underscored a striking reality: Saudi Arabia is now one of the most important façade engineering markets in the world. Conference discussions and presentations deconstructed the details; from the ever-increasing scale of the Kingdom’s giga-projects and the engineering impact of harsh desert climates to the top-down innovation drive of the Public Investment Fund (PIF) amidst the current ripple effects on the global supply chain.

Saudi Arabia: One of the World’s Largest Façade Market

The 6th edition of ZAK Riyadh included insight from Schlaich Bergemann Partner (SBP) on the latest in post-breakage safety; Kuraray led innovative solutions with acoustic interlayering to tackle challenges in desert sound and heat; and Fassada steel unveiled a hybrid steel curtain wall system.

Some KSA cities’ harsh climates add to the challenge: soaring temperatures, intense UV exposure, and frequent sandstorms force façades to meet performance levels rarely demanded elsewhere. Emerging as a global leader in mega construction projects, Saudi Arabia accounts for more than 40 percent of the Middle East’s project value.

With deep-pocketed clients like PIF insisting on advanced specifications, international suppliers are racing to develop technologies, “Designed for KSA.” The result is a wave of new materials and systems that are setting up new global benchmarks for façade design and engineering.

Among the most compelling:

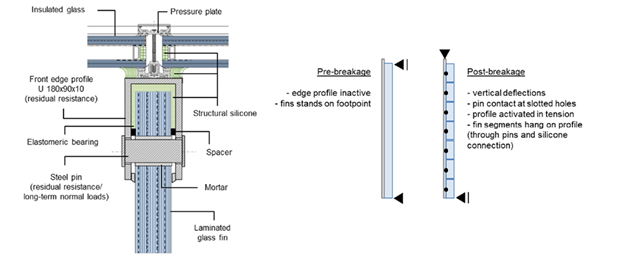

Ensuring Post-Breakage Safety in Iconic Designs

One innovative technical insight at ZAK Riyadh was how engineers are designing façades to remain safe even after glass breakage. In a session by David Sommer, Managing Director at Schlaich Bergermann Partner, examined a variety of Riyadh structures and their related solutions. One standout is the 16-metre-high laminated glass panel that delivers a fully transparent façade, an elegant structural move and reportedly among the world’s ten tallest, but it also sharpens the due-diligence question: what redundant support strategy is in place if the pane fails or is compromised?

“When fins break, we make sure the façade is hanging and not falling,” Sommer explained. A hidden steel U-channel is tucked along the fin’s edge, idle in normal conditions, but designed to capture and retain the fractured glass if failure occurs, holding the fin safely in place.

It keeps the façade stable and the site safe after breakage. In effect, it’s a silent, invisible backup frame: if a panel shatters, the envelope still maintains structural integrity until permanent replacement and remediation can be executed.

Urban Sound and Heat: New Acoustic Interlayers

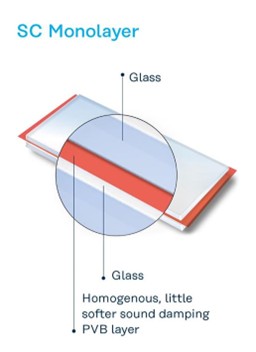

Big cities environment was a recurring theme, prompting innovations to tackle noise and solar heat. KSA Engineering Consultant at Kuraray, Davide Malizia, introduced an advanced acoustic laminated glass interlayer engineered for harsh climates. A PVB film provides superior sound damping and solar control in one package. “Standard PVB interlayers struggle in the Middle East heat,” Malizia noted. “Our acoustic interlayer can cut noise transmission by around 38dB” while also reducing solar heat gain by using another film; an important benefit in cities like Riyadh where traffic and 50 °C summer days can coincide. Malizia emphasized that these performance gains do not come at the expense of clarity or safety; instead, by tailoring the polymer chemistry to local conditions (for example, ensuring stability under high UV and temperature).

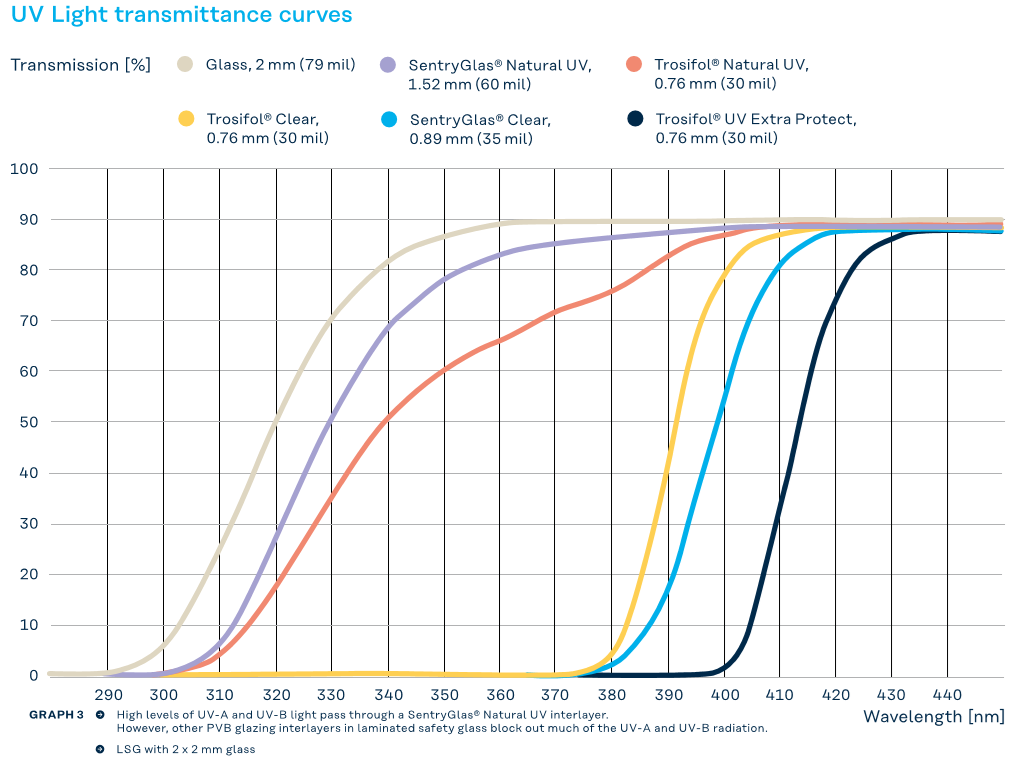

Alongside acoustic and thermal performance, laminated glass can also be engineered for UV control. Conventional laminates transmit UV with minimal attenuation, while UV-blocking interlayers can be specified when long-term protection of interiors is a priority. The graph shown illustrates how different PVB interlayers either maintain near-natural UV transmission or substantially cut UV-A and UV-B penetration.

In sunny conditions, this becomes a practical design choice rather than a niche feature, particularly for hospitality, retail, and high-end residential interiors exposed to intense solar radiation. Such interlayers illustrate how material science is stepping up to meet Saudi’s unique acoustic and climatic demands.

Bridging Stick and Unitized Systems: Hybrid Steel Façades

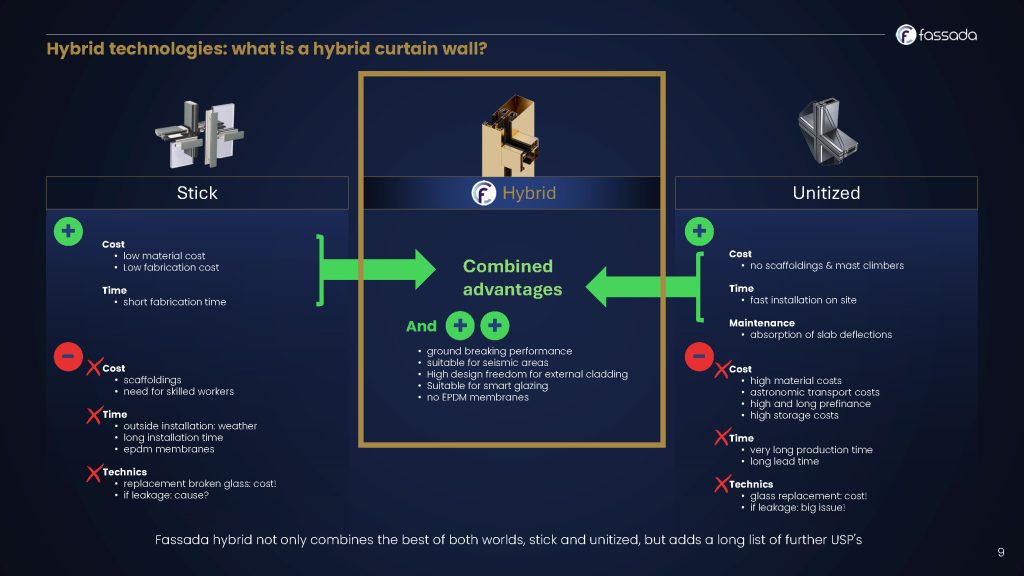

Façade assembly methods are also evolving under Saudi Arabia’s mega-project pressures. Eric Claeys, founding partner of Fassada Steel, unveiled a hybrid steel curtain wall system that effectively bridges traditional stick-built and unitized approaches. “We basically took the best of both worlds,” Claeys said. “The result is a façade that can be assembled faster in remote desert sites, no external scaffolding needed, yet it’s as precise and factory-built as a unitized system.”

The hybrid design features inside-out construction: all major installation steps can be done from the building interior, a huge plus for worker safety and efficiency in Saudi’s climate. In addition, maintenance costs will be reduced since it can be done from the inside during operational phase of the building, which will be more beneficial on the long run, and will serve sustainability.

As shown in the infographic, Fassada’s hybrid curtain wall concept merges stick-built and unitized systems. It combines each approach’s advantages (green) while eliminating many drawbacks (red) and adds benefits like seismic resilience and interior-only installation.

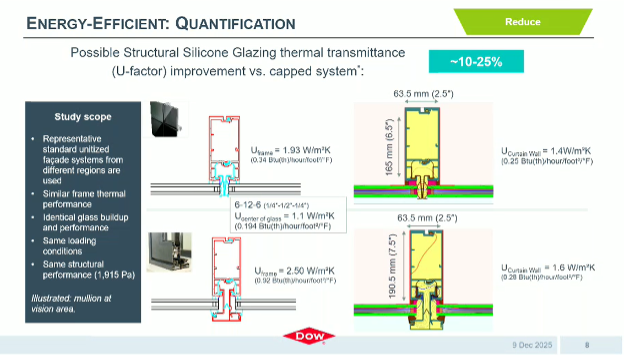

Silicone Glazing that Cuts Carbon and Energy

Sustainability also surfaced as a key theme, not through slogans, but through smarter façade detailing. Valeriya Chernikova, EMEA Marketing Manager for Dow Consumer Solutions, showed how structural silicone glazing (SSG) can deliver lighter, more energy-efficient envelopes by using high-strength silicone bonding to eliminate aluminum pressure plates and caps, often the culprit behind major thermal bridges. Regional case studies suggested that moving from a capped curtain wall to SSG can improve U-values by roughly 10–25%, with the uplift varying by climate zone and system configuration.

“You’re essentially taking a big aluminum heat-conductor out of the façade,” she said, reducing heat transfer indoors and lowering cooling loads. Bonding can also allow slimmer frames or reduced window reinforcements.

Beyond operational energy savings, the material efficiency gains are significant. Dow’s analysis indicates structural silicone bonding can cut curtain wall aluminum content by up to 15%, reducing façade weight and dead load. Every kilogram of aluminum avoided also lowers embodied carbon, given aluminum’s energy-intensive production. As Chernikova put it: “We get lower U-values for better thermal performance, and we use less aluminum, so we improve both operational and embodied carbon at the same time.” With Saudi Arabia pursuing ambitious sustainability goals, these detailing innovations are increasingly valuable.

Parametric Façades as Architectural Identity

The conference closed with a panel on how iconic architecture and façade engineering go hand-in-hand in Saudi’s development. In a special panel on the King Abdullah Financial District (KAFD) Metro Station, Filippo Innocenti, Director at Zaha Hadid Architects described the role of the façade in defining the project’s identity. The station’s enveloping skin is a flowing, parametric design of geometrically complex glass and steel panels, recognizable as a ZHA creation.

“At KAFD, the façade isn’t just a cladding – it is the architecture,” Innocenti remarked. “The form of the building and the envelope are one and the same, driven by the same parametric logic and vision.”

Achieving this meant close collaboration between architects and engineers: the façade’s freeform geometry required advanced engineering solutions, including custom structural glass systems and digitally fabricated cladding units. Importantly, the design is not only iconic but functional for Riyadh’s climate. The curved exterior integrates shading and high-performance glazing to maximize natural light while minimizing heat gain, and it stands up to desert conditions with robust materials and detailing. Innocenti noted that in the Middle East, such landmark projects illustrate a broader point: façades have become the face of the building, central to both expression and performance.

Nowhere is this more evident than Saudi Arabia, where architecture’s boldest visions are being matched by equally bold façade engineering. “The envelope is doing so much heavy lifting aesthetically, structurally, environmentally that it’s fundamentally shaping the identity of these projects,” he said. The KAFD Metro Station, slated to become a city icon, exemplifies how cutting-edge façade design is contributing to the architectural legacy of Riyadh.

A New Benchmark for Façades

Over the course of the ZAK World of Façades Riyadh 2025 event, one message rang clear: Saudi Arabia’s conversations, applications, and innovations in the façade industry are rapidly evolving. The combination of limitless ambition, demanding climate, and strong client leadership is yielding solutions that break previous limits in design, performance, and scale.

From glass that won’t fail catastrophically to interlayers that tame heat and noise, from hybrid frames that simplify construction to silicone bonds that save energy and carbon; the technologies showcased in Riyadh are poised to influence projects far beyond the Kingdom’s borders.

For façade engineers and building envelope specialists, Saudi Arabia today is not just a booming market, it’s a live testing ground for the future of façade engineering. As the country’s giga-projects continue to flourish they are setting new standards that the rest of the world will be watching closely. In the words of one speaker, “Riyadh is where the envelope is being pushed, literally and figuratively.”